Ensuring worker safety is a critical responsibility for any organization. Beyond complying with OSHA regulations, a robust safety program protects employees, reduces accidents, and improves overall operational efficiency. Implementing a systematic procedure using Microsoft Excel allows organizations to track compliance, analyze data, and foster a culture of safety through both direct and indirect reporting systems.

The objective of this procedure is to improve OSHA worker safety compliance through structured reporting and tracking using Microsoft Excel. By leveraging this system, organizations can streamline work assignment cycle times, identify areas for improvement, and enhance productivity while maintaining a safe work environment.

1. Setting Up the Excel Workbook

The first step in implementing a safety compliance program is to establish a well-organized Excel workbook. This workbook will serve as the central hub for all safety-related data, allowing management to track employee compliance, training, incidents, inspections, feedback, and cycle times.

A. Create a New Workbook

- Open Microsoft Excel.

- Create a new workbook and save it with a descriptive title, e.g., “OSHA Worker Safety Program.xlsx.”

B. Set Up Sheets

For clarity and ease of use, create the following sheets within the workbook:

- Employee Data – Tracks employee information, training status, and compliance.

- Training Records – Maintains detailed training session records.

- Incident Reports – Documents workplace incidents and corrective actions.

- Safety Inspections – Captures inspection results and findings.

- Safety Feedback – Collects employee feedback regarding safety.

- Cycle Time Analysis – Compares operational cycle times before and after safety program implementation.

- Compliance Summary – Summarizes all compliance metrics for analysis and reporting.

By structuring the workbook into dedicated sheets, organizations can maintain organized records and simplify data analysis.

2. Employee Data Sheet

The Employee Data sheet provides a comprehensive record of employee-specific safety compliance metrics.

A. Columns Setup

- Column A: Employee ID

- Column B: Employee Name

- Column C: Department

- Column D: Date of Hire

- Column E: PPE Compliance (Y/N)

- Column F: Training Completed (Y/N)

- Column G: Last Training Date

- Column H: Incidents (Y/N)

- Column I: Incident Details

- Column J: Last Inspection Date

- Column K: Compliance Status (Compliant/Non-Compliant)

B. Data Entry

Maintain regular updates with employee information, training status, incidents, and inspection results. Accurate and timely data entry ensures reliable tracking and reporting.

3. Training Records Sheet

The Training Records sheet records all safety training sessions for employees.

A. Columns Setup

- Column A: Training ID

- Column B: Employee ID

- Column C: Training Topic

- Column D: Training Date

- Column E: Trainer Name

- Column F: Completion Status (Y/N)

B. Data Entry

Record each training session along with the completion status. This data helps track skill gaps, ensure OSHA compliance, and schedule refresher sessions.

4. Incident Reports Sheet

The Incident Reports sheet captures details of workplace incidents, helping organizations respond and prevent future occurrences.

A. Columns Setup

- Column A: Incident ID

- Column B: Employee ID

- Column C: Date of Incident

- Column D: Type of Incident

- Column E: Severity

- Column F: Description

- Column G: Corrective Actions

- Column H: Follow-Up Date

B. Data Entry

Document every incident, including the type, severity, and corrective actions taken. This information supports risk analysis and regulatory reporting.

5. Safety Inspections Sheet

Safety inspections help identify hazards and assess compliance across departments.

A. Columns Setup

- Column A: Inspection ID

- Column B: Inspector Name

- Column C: Date of Inspection

- Column D: Department

- Column E: Findings

- Column F: Compliance Status (Compliant/Non-Compliant)

- Column G: Follow-Up Actions

B. Data Entry

Record findings and compliance status after each inspection. Ensure timely follow-up for non-compliant issues to maintain a safe work environment.

6. Safety Feedback Sheet

Employee feedback is essential to promoting a culture of safety.

A. Columns Setup

- Column A: Feedback ID

- Column B: Employee ID

- Column C: Department

- Column D: Date of Feedback

- Column E: Feedback Type (Positive/Negative)

- Column F: Description

- Column G: Action Taken

- Column H: Follow-Up Date

B. Data Entry

Record feedback from employees and document actions taken. Incorporating employee input strengthens engagement and helps identify overlooked safety issues.

7. Cycle Time Analysis Sheet

Tracking cycle times helps measure the operational impact of safety programs.

A. Columns Setup

- Column A: Task ID

- Column B: Department

- Column C: Task Description

- Column D: Cycle Time (Before Safety Implementation)

- Column E: Cycle Time (After Safety Implementation)

- Column F: Difference in Cycle Time

- Column G: Comments

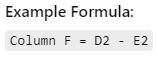

B. Data Calculation

Compare cycle times before and after safety implementation.

Analyzing differences helps demonstrate the efficiency gains associated with improved safety practices.

8. Compliance Summary Sheet

The Compliance Summary sheet aggregates all key metrics to provide a clear overview of safety compliance.

A. Overview

Summarize compliance data and operational metrics for before-and-after comparisons.

B. Columns Setup

- Column A: Department

- Column B: Total Employees

- Column C: PPE Compliance Rate (Before)

- Column D: PPE Compliance Rate (After)

- Column E: Training Completion Rate (Before)

- Column F: Training Completion Rate (After)

- Column G: Incident Rate (Before)

- Column H: Incident Rate (After)

- Column I: Compliance Rate (Before)

- Column J: Compliance Rate (After)

- Column K: Average Cycle Time (Before)

- Column L: Average Cycle Time (After)

C. Data Calculation

Use Excel formulas to calculate compliance rates and cycle times.

Example Formula for PPE Compliance Rate:=COUNTIF('Employee Data'!E:E, "Y") / COUNTA('Employee Data'!A:A)

This allows management to measure improvements and identify departments needing additional support.

9. Implementing the Safety Compliance Program

Safety compliance relies on both direct and indirect reporting systems.

A. Direct Methods

- Training Programs: Conduct regular, comprehensive safety training for all employees.

- PPE Distribution: Ensure employees have required personal protective equipment and know how to use it.

- Regular Inspections: Schedule frequent safety inspections to assess compliance.

- Incident Reporting: Establish a clear, accessible incident reporting system.

B. Indirect Methods

- Safety Culture Promotion: Promote safety-first values via newsletters, posters, and team meetings.

- Feedback Mechanism: Enable anonymous reporting for employee concerns and suggestions.

- Recognition Programs: Reward departments and employees demonstrating excellent safety practices.

- Cycle Time Tracking: Monitor task efficiency to show productivity improvements linked to safety measures.

10. Before and After Comparison

Evaluating safety program impact requires a structured comparison.

A. Data Collection (Before)

Collect baseline data, such as PPE compliance, training completion, incident rates, compliance status, and cycle times, from a defined period (e.g., Q1 2024).

B. Data Collection (After)

Collect the same metrics after program implementation (e.g., Q3 2024).

C. Analysis

Use the Compliance Summary Sheet to compare before-and-after results. Calculate improvement percentages and identify trends.

D. Reporting

Create charts and graphs to visually represent improvements. Prepare a report summarizing the safety program’s impact and benefits.

11. Continuous Improvement

Safety programs are most effective when continuously reviewed and refined.

A. Regular Reviews

Schedule monthly or quarterly reviews to assess program effectiveness. Update Excel sheets with new data and track ongoing compliance.

B. Feedback Integration

Incorporate employee feedback to enhance safety practices. Identify recurring hazards or issues and adjust policies accordingly.

C. Adaptation

Refine training, inspections, and reporting systems based on data insights. Continuous adaptation ensures the program evolves with organizational needs and regulatory updates.

Conclusion

By implementing OSHA worker safety procedures using Microsoft Excel, organizations gain a systematic approach to tracking compliance, reporting incidents, and improving overall workplace safety. Direct reporting methods, such as inspections and training, ensure immediate compliance, while indirect methods, such as feedback and culture promotion, reinforce a proactive safety mindset.

The before-and-after comparison highlights the tangible benefits of the program, including improved PPE compliance, reduced incident rates, and enhanced cycle times. Continuous monitoring and improvement foster a culture of safety, protect employees, and contribute to increased operational efficiency and productivity.

This structured approach demonstrates that safety compliance is not only a regulatory requirement but also a strategic initiative that directly impacts performance, employee well-being, and organizational success.

Disclaimer:

This procedure is provided for educational and operational guidance purposes only. Compliance with OSHA and local safety regulations remains the responsibility of the organization. Microsoft Excel serves as a tracking and analysis tool and does not replace required inspections, training, or regulatory compliance measures.